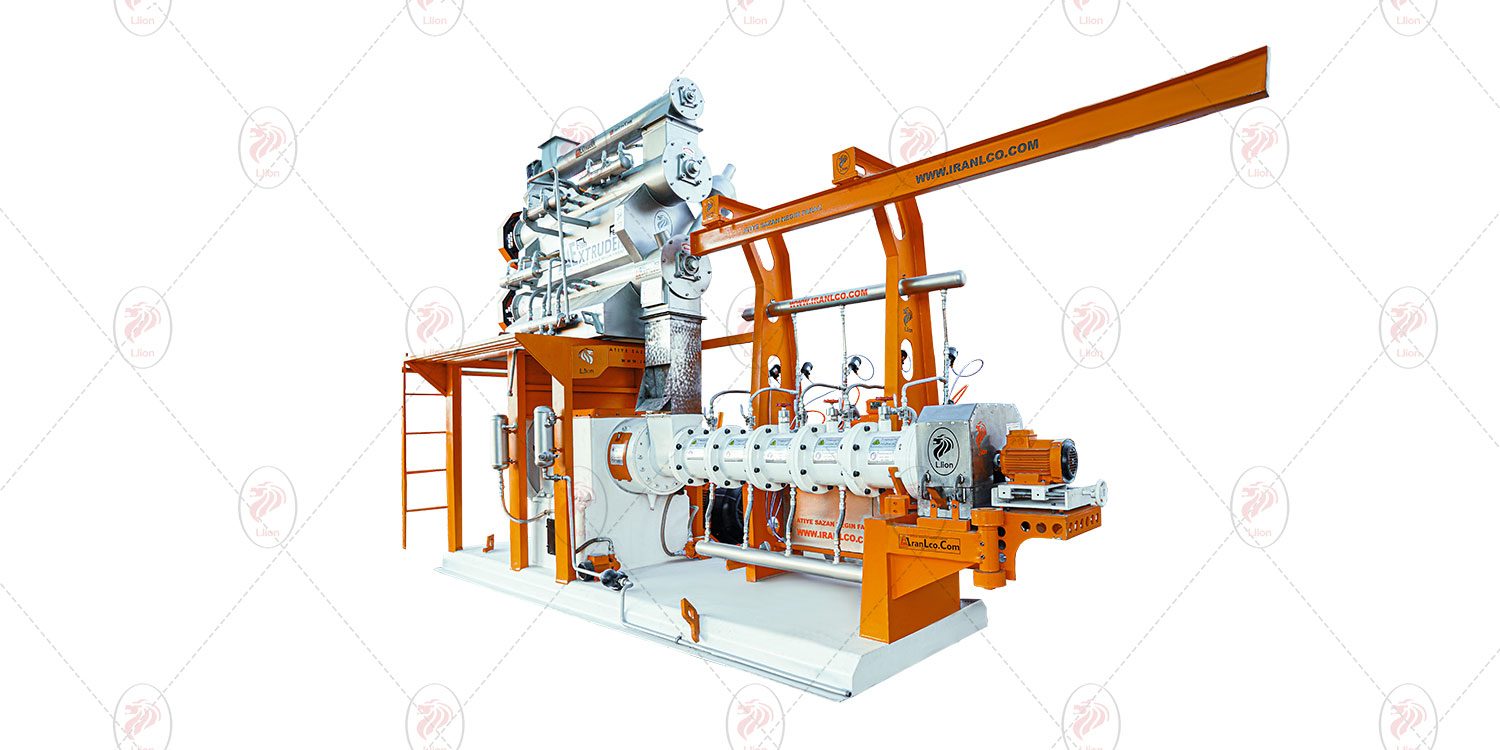

Extruder Technology Application for Shrimp Feed Production

Atiye Sazan Negin Faraz Co. offers the advanced technology for shrimp feed production

The today’s need for cost effective and at the same time, high quality feed clearly indicates that the best feed production requires the specialized processing technology. L.lion is among the leading companies in the field of providing technologies, systems, and services related to the advanced industrial equipment for aquatic feed industry.

Advanced Technologies

The production of high-quality shrimp feed depends on several factors, such as the raw materials and formulation, however, the use of equipment with appropriate characteristics is the key to the production of high quality feed.

L.lion provides the aquatic feed producers with advanced technology and equipment causing competitive advantage.

The main machinery used for shrimp feed production

- Hammer mill

- Pellet press

- Mixer

- Dryer

- Conditioner

- Vacuum coater

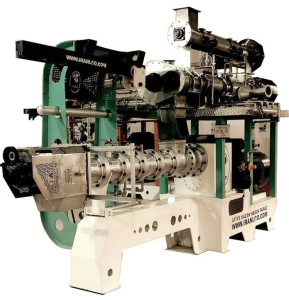

- Extruder

Shrimp feed

Having access to a flexible technology to match a wide range of nutritional needs and behaviors of different growth periods is of paramount importance for appropriate growth of shrimp. The place where the shrimp is cultivated is also another factor affecting the way in which the shrimp feed is produced. The use of tanks with recirculation may require a product different from when the shrimp is grown in an outdoor pond. L.lion has appropriate solutions for shrimp feed production.

The production of sinking feed with high stability in water is regarded as the first challenge to the shrimp production. This is possible by gelatinization of starch by grounding, feed conditioning, processing, post conditioning and extrusion.

Extruded shrimp feed

Usually, starch causes pellets to bind together. Starch is, however, of a low nutritional value for shrimp. Replacing starch with other protein resources increases the nutritional value of the feed. The raw materials are fine ground using high-speed hammer mills. In the next stage, the particles are reduced in size via pulverizer machine until the required size is reached.

The greater size particles return to the process line via a screener and are ground again. All dry materials are completely mixed using a mixer. The extrusion technology allows feed producers to produce feed with low starch content.

Therefore, the starch content reduces from 25%-35% to 15%-18%, and finally improves feed conversion ratio and leads to higher quality of the end product. Moreover, the extrusion technology allows for producing starter feed in extruder without the need for a crumbler.

Shrimp extruded feed advantages

- Better energy conversion

- Lower formulation cost

- More diversity of raw materials

- High degree of porosity

- Low density

- Higher stability in water

- Lower environmental pollution

Frequently Asked Questions (FAQ): Extruder Technology Application for Shrimp Feed Production

- What is the role of extruder technology in shrimp feed production?

This technology is used to cook, shape, and enhance the nutritional value and digestibility of shrimp feed, ensuring consistent pellet quality and stability in water.

- Why is extrusion preferred over traditional pelleting methods?

Extrusion allows better control over temperature, moisture, and pressure, which improves feed conversion ratio (FCR), pellet durability, and nutrient availability.

- What types of extruders are used in shrimp feed processing?

Both single-screw and twin-screw extruders are used. Twin-screw extruders provide better mixing and cooking control, ideal for high-protein shrimp feed formulations.

- How does extrusion improve water stability of shrimp feed?

The high-temperature and pressure process during extrusion gelatinizes starch and denatures proteins, creating compact pellets that resist disintegration in water.

- Can this technology reduce feed waste in shrimp farming?

Yes. The uniform size and high water stability of extruded feed minimize feed loss and improve shrimp feeding efficiency.

- What ingredients are suitable for extruded shrimp feed?

Common ingredients include fish meal, soybean meal, wheat flour, binders, vitamins, minerals, and functional additives such as enzymes or probiotics.

- How does extrusion affect the nutritional quality of shrimp feed?

Extrusion enhances digestibility, inactivates anti-nutritional factors, and allows the incorporation of heat-sensitive additives post-extrusion.

- What are the main parameters controlled in an extruder?

Key parameters include temperature, screw speed, moisture content, die design, and pressure — all of which influence pellet quality.

- How is floating or sinking behavior of shrimp feed controlled?

By adjusting moisture, density, and die configuration in the extruder, manufacturers can produce sinking or slow-sinking pellets as required for shrimp feeding habits.

- What are the energy requirements for shrimp feed extrusion?

Energy consumption depends on feed formulation, moisture level, and extruder type; modern systems are designed for high efficiency and low energy use.

- What post-extrusion processes are needed?

Post-extrusion steps include drying, coating with oil or attractants, cooling, and sieving to achieve the desired texture and nutritional profile.

- How can extrusion technology help in sustainable shrimp farming?

It enables the use of alternative protein sources, reduces feed wastage, and supports environmentally friendly aquaculture practices.