Soy Extruder: Introduction and Significance of Human-Grade Soy Extruder

In recent years, the global food industry has witnessed a remarkable shift toward plant-based proteins, driven by growing consumer awareness of health, sustainability, and ethical considerations. Among these plant-derived proteins, soy has emerged as a primary candidate due to its high protein content, well-balanced amino acid profile, affordability, and wide availability. Unlike many other plant proteins, soy provides all essential amino acids, making it a complete protein source suitable for human nutrition. As demand for human-grade protein ingredients increases, the need for efficient, scalable, and hygienic processing technologies becomes critical. One of the most effective methods for transforming raw soybeans or soy materials into high-quality, human-edible ingredients is extrusion processing.

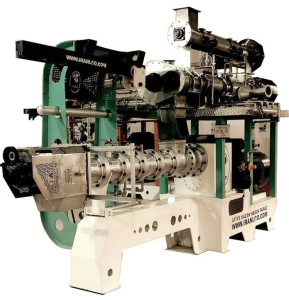

Click to see how a human-grade soy extruder works.

- Rising Demand for Human-Grade Plant Proteins

The global population is projected to reach nearly 9.8 billion by 2050, intensifying the pressure on sustainable protein production systems. In response, plant-based diets have grown in popularity, encompassing flexitarian, vegetarian, and vegan eating patterns. Human-grade soy products play a central role in this transition, as they provide a nutritious, cost-effective alternative to animal-derived proteins.

Market research indicates that the plant-based protein sector is growing at a compound annual growth rate (CAGR) exceeding 12% globally. Within this sector, human-grade soy protein ingredients—used in meat analogues, protein bars, beverages, and nutritional supplements—represent a substantial portion of the revenue stream. Extrusion technology enables producers to scale operations efficiently while maintaining high product consistency and food safety standards, which is essential for human consumption markets.

- Why Human-Grade Extrusion Matters

Human-grade extrusion refers to processing conditions and equipment standards that produce ingredients safe and suitable for direct human consumption. Unlike animal feed, which may tolerate higher microbial loads or variations in nutrient consistency, human-grade extrusion requires:

Stringent hygiene controls: All components in contact with soy must comply with food-grade material standards, be cleanable in place (CIP), and minimize crevices or potential contamination points.

Process consistency: Uniform moisture, temperature, and shear conditions are necessary to ensure reproducible protein denaturation, texture formation, and nutrient retention.

Nutritional preservation: High-quality extrudates must maintain essential amino acids, digestibility, and minimize anti-nutritional factors such as trypsin inhibitors and lectins.

Traceability: Digital monitoring and data logging allow batch-by-batch verification for compliance with food safety regulations such as HACCP and ISO 22000.

By meeting these requirements, human-grade extrusion transforms raw soy into versatile ingredients for a wide array of food products while adhering to strict regulatory standards.

- Functional and Nutritional Advantages

Extrusion processing offers several functional and nutritional benefits for human-grade soy protein production:

- Enhanced Protein Digestibility: Controlled thermal and mechanical energy during extrusion unfolds protein structures, making them more digestible and bioavailable. Studies demonstrate that high-moisture extrusion significantly increases in vitro protein digestibility for both soy protein isolate (SPI) and soy protein concentrate (SPC).

- Texturization for Meat Analogues: Extrusion aligns protein fibers into fibrous structures resembling animal muscle. This is critical for producing plant-based meat analogues such as burgers, sausages, and minced protein products.

- Reduction of Anti-Nutritional Factors: Properly designed extrusion conditions inactivate trypsin inhibitors, lectins, and other compounds that may impair nutrient absorption.

- Flavor and Sensory Improvements: Extrusion can reduce the characteristic “beany” flavor of soy by deactivating lipoxygenase enzymes, producing more neutral-tasting ingredients suitable for diverse food applications.

- Versatility Across Feedstocks: Human-grade extrusion accommodates various soy inputs, including defatted soy flour, full-fat soy, and soy protein concentrates. Each feedstock requires tailored process parameters to achieve optimal texture, expansion, and nutritional quality.

These functional advantages make extrusion indispensable for producing high-value, human-grade soy ingredients for modern food applications.

- Industrial and Market Implications

The ability to reliably produce human-grade soy protein ingredients via extrusion has profound implications for the food industry:

Scalability: Industrial extruders allow seamless transition from pilot-scale production to full-scale manufacturing without compromising quality.

Customization: Process parameters (temperature, moisture, screw speed, die design) can be adjusted to produce products with specific textures, densities, and rehydration properties.

Nutritional Fortification: Extrusion supports the addition of micronutrients, vitamins, minerals, and flavor enhancers while minimizing nutrient degradation due to the short residence time.

Global Accessibility: Soybeans are cultivated worldwide, providing a reliable protein source for both developed and emerging markets.

Extrusion technology not only addresses the growing consumer demand for plant-based proteins but also supports sustainability objectives by optimizing energy usage, minimizing water consumption, and reducing waste during processing.

- Overview of the Extrusion Process

In human-grade soy extrusion, raw soy materials are first cleaned, dehulled, and ground into flakes or flour. Moisture and other pre-conditioning parameters are adjusted to achieve a uniform feedstock. The extruder then subjects the soy to precise combinations of heat, pressure, and shear, transforming the protein matrix into a textured, digestible, and safe product.

Key variables influencing extrusion outcomes include:

Temperature: Critical for protein denaturation, starch gelatinization, and microbial inactivation.

Moisture content: Determines texture (low moisture for snacks, high moisture for meat analogues) and energy efficiency.

Screw speed and torque: Affect residence time, shear intensity, and texturization.

Die configuration and cutting systems: Shape the final product, control expansion, and maintain uniformity.

These controlled parameters allow manufacturers to produce a wide range of human-grade soy products while ensuring repeatable quality.

Equipment Design and Technical Considerations of Human-Grade Soy Extruder

Human-grade soy extrusion requires carefully engineered equipment to ensure safety, hygiene, and consistent product quality. Unlike conventional animal-feed extrusion, human-grade production demands stricter design specifications, robust process control, and precise monitoring of mechanical and thermal variables. In this section, we examine the key components and technical considerations that define a high-performance extruder for human-edible soy products.

- Screw and Barrel Configuration

The screw and barrel assembly is the heart of the extrusion system, determining the extent of shear, residence time, pressure build-up, and thermal energy distribution. Manufacturers typically choose between single-screw and twin-screw configurations, each offering unique advantages:

Single-screw extruders are simpler, cost-effective, and easier to maintain, but offer limited control over shear and mixing.

Twin-screw extruders provide superior control of temperature, pressure, and material flow, making them ideal for high-moisture extrusion and textured soy protein production.

Screw design parameters include:

Screw diameter and length-to-diameter ratio (L/D): A longer L/D ratio increases residence time and allows thorough mixing.

Screw elements: Conveying, kneading, and reverse elements create controlled shear and material transport.

Screw speed and torque: Typical human-grade operations use 250–500 rpm, maintaining consistent torque to avoid slippage and degradation.

The barrel, often segmented into multiple temperature zones, allows precise control of heat input, enabling protein denaturation, starch gelatinization, and microbial inactivation without burning or scorching.

- Hygienic and Food-Grade Design

For human-grade applications, extruder components must comply with stringent hygienic standards:

Material selection: Stainless steel (typically 316L) or food-grade coated alloys for all parts in contact with soy.

CIP (Clean-In-Place) capability: Accessible ports and minimal crevices facilitate efficient cleaning, reducing microbial risk.

Dust and particle control: Enclosures and negative-pressure systems prevent airborne contamination.

Surface finish: Smooth, polished surfaces prevent protein or oil residues from adhering, minimizing biofilm formation.

Proper hygienic design not only protects product quality but also simplifies compliance with regulatory frameworks like ISO 22000, HACCP, and EHEDG guidelines.

- Die Design and Product Expansion

The die determines the final product geometry, expansion, and texture. Considerations include:

Shape and size: Circular openings for snacks, slits or annular dies for textured soy protein (TSP).

Pressure and expansion control: Proper die design ensures uniform puffing and prevents collapse.

Cooling mechanisms: For high-moisture extrudates, cooled dies preserve fibrous structures and reduce microbial risk.

Advanced die designs enable the production of consistent, high-quality human-grade soy ingredients suitable for rehydration, cooking, and incorporation into various food products.

- Instrumentation and Process Control

Modern extruders integrate sophisticated monitoring systems for real-time control of process variables:

Temperature sensors: Distributed along barrel zones and die to maintain uniform thermal profiles.

Torque and screw load sensors: Ensure mechanical stability and prevent overloading or slippage.

Moisture control: Automated feeders adjust water content to achieve target levels (20–35% for human-grade products).

Die pressure and flow monitoring: Prevent blockages and maintain uniform product density.

Automation allows for precise data logging and traceability, essential for quality assurance and regulatory compliance.

- Integration with Upstream and Downstream Systems

Efficiency and product quality depend on seamless integration with upstream and downstream operations:

Upstream preparation: Cleaning, dehulling, flaking, and defatting must produce consistent feedstock. Pre-conditioning and tempering zones ensure uniform moisture and particle size.

Downstream handling: Cooling, drying, cutting, and packaging systems must maintain the integrity of the extrudate. Specialized conveyors and moisture-controlled environments prevent contamination and textural collapse.

This end-to-end integration ensures the extruder operates at optimal efficiency while producing high-quality, human-grade soy ingredients.

- Feedstock Considerations

Feedstock quality directly affects extrusion outcomes. Key points include:

Soybean type: High-protein varieties with minimal anti-nutritional factors are preferred.

Defatted vs. full-fat soy: Defatted soy offers better flavor stability and texture control, while full-fat soy requires tighter process control.

Moisture content: Pre-adjusted to ensure plasticization and avoid over-shearing or insufficient expansion.

Particle size: Uniform particles prevent clogging and promote consistent product structure.

Pre-conditioning systems, such as steam injection or tempering zones, enhance plasticization and improve textural outcomes.

- Thermal Management

Temperature control is critical in human-grade extrusion:

Protein denaturation: Achieved without nutrient loss.

Microbial inactivation: High-temperature zones ensure food safety.

Anti-nutritional factor reduction: Trypsin inhibitors and lectins are neutralized through controlled heat and shear.

Texture optimization: Temperature gradients along the barrel influence fibrous structure formation in TSP and high-moisture products.

Modern extruders feature multi-zone heating with independent control and feedback loops for precise thermal management.

- Energy Efficiency and Sustainability

Contemporary human-grade extruders integrate energy-saving technologies:

Variable frequency drives (VFDs): Optimize screw and feeder motor energy consumption.

Heat recovery systems: Capture exhaust heat for pre-conditioning or drying operations.

Optimized process scheduling: Reduces idle times, over-shearing, and energy waste.

These measures reduce operational costs, improve sustainability, and support green manufacturing initiatives.

- Safety and Maintenance Considerations

Human-grade extruders operate under high pressure, temperature, and shear. Key safety practices include:

Protective enclosures and interlocks: Prevent operator injury.

Emergency shutdown procedures: Ensures safe halting of the process.

Regular maintenance: Lubrication, screw/barrel inspection, and sensor recalibration preserve equipment lifespan and hygiene.

CIP and cleaning schedules: Maintain sanitary standards without disassembly, essential for food-grade compliance.

Predictive maintenance using vibration, torque, and temperature sensors allows early detection of wear, reducing unplanned downtime.

Summary

A human-grade soy extruder is a sophisticated combination of mechanical engineering, thermal science, and hygienic design. Its performance depends on:

Optimized screw and barrel configuration

Hygienic, food-grade construction

Precision die design

Advanced instrumentation and automation

Integration with upstream and downstream processes

Controlled feedstock preparation

Energy-efficient and safe operation

This carefully engineered system ensures that raw soy is transformed into consistent, safe, and high-quality ingredients suitable for human consumption, supporting the rapidly growing plant-based food market.

Process, Operating Parameters, and Quality Control of Human-Grade Soy Extruder

The transformation of raw soy materials into high-quality, human-edible protein ingredients relies on precise control of the extrusion process. In human-grade soy extrusion, mechanical energy, heat, pressure, and moisture interact within the extruder to produce safe, functional, and consistent products. Understanding and optimizing each parameter is critical for maximizing digestibility, texture, and overall product quality.

- Temperature Management

Temperature is one of the most critical variables in soy extrusion. Human-grade extruders operate across a wide temperature range depending on the product type:

Low-moisture extrusion: Typically 120–150 °C, producing expanded snacks or protein crisps.

High-moisture extrusion: Often 140–170 °C, used for textured soy proteins (TSP) and meat analogues.

Implications of temperature control:

Too low: Incomplete protein denaturation, remaining anti-nutritional factors, poor microbial inactivation.

Too high: Excessive browning, nutrient degradation, burnt flavors, and potential equipment wear.

Modern extruders feature multiple barrel heating zones with independent controllers and feedback loops, ensuring uniform heat distribution and precise control over protein unfolding, starch gelatinization, and fiber alignment.

- Moisture Content

Moisture acts as a plasticizer, directly influencing product texture and process efficiency:

Low moisture (20–25%): Produces expanded, crunchy extrudates suitable for snack foods and high-protein cereals.

High moisture (50–70%): Essential for fibrous structures mimicking meat, used in high-moisture meat analogues (HMMA).

Automatic moisture-control systems integrated with gravimetric feeders provide continuous regulation during extrusion, ensuring consistency and preventing scorching or poor expansion. Pre-conditioning steps, including steam injection and tempering, improve feed uniformity and extrusion performance.

- Screw Speed and Torque

Screw speed and torque determine residence time, shear intensity, and mixing efficiency:

High screw speed: Increases shear, enhancing texturization but may damage sensitive amino acids.

Low screw speed: Produces denser, less fibrous structures with smoother textures.

Twin-screw human-grade extruders typically operate between 250–500 rpm, maintaining consistent torque. Torque sensors provide real-time feedback to the control system, ensuring mechanical stability and uniform processing.

- Feed Rate and Pressure

A stable feed rate balances with screw speed and barrel pressure:

Gravimetric feeders are preferred for precise dosing in large-scale operations.

Die pressure: Usually maintained between 30–80 bar, depending on product form and expansion requirements.

Pressure and temperature together govern starch gelatinization and protein texturization, both critical for human-grade soy products. Sudden pressure drops at the die facilitate expansion and texture formation, while consistent feed ensures uniform density and shape.

- Die Configuration and Cutting Systems

The die plays a critical role in shaping and expanding the final product:

Snacks: Circular dies produce puffed, crunchy extrudates.

Textured soy protein (TSP): Slit or annular dies align protein fibers, creating meat-like fibrous structures.

Cutting systems synchronized with extruder output ensure uniform size and prevent smearing or deformation. High-moisture extrudates often require water-cooled dies to preserve structure and minimize microbial growth.

- Process Optimization

Human-grade soy extrusion requires continuous fine-tuning of process parameters to achieve:

Maximum protein digestibility (PDCAAS > 0.9)

Minimal residual anti-nutritional factors (<1 mg/g trypsin inhibitor)

Uniform color and absence of burnt odors

Consistent water-holding and oil-binding capacities

Controlled bulk density for easy downstream handling

A process optimization matrix is commonly employed, adjusting temperature, moisture, screw speed, and die configuration incrementally to balance quality and throughput. PLC-based automation enables real-time adjustments, data logging, and traceability essential for regulatory compliance.

- Nutritional and Functional Enhancements

Extrusion enhances both the nutritional and functional properties of soy protein:

Protein solubility: Increased for applications in beverages, dairy alternatives, and sports nutrition.

Beany flavor reduction: Lipoxygenase inactivation leads to neutral-tasting products.

Formation of fibrous protein networks: Essential for meat analogues with realistic texture.

Fortification: Short residence times allow addition of vitamins, minerals, or probiotics without significant degradation.

These improvements expand the versatility of human-grade soy ingredients across various food applications.

- Quality Control and Testing

Human-grade products must meet stringent quality criteria. Common testing parameters include:

Moisture content and water activity (aw): Ensures shelf stability and microbial safety.

Protein dispersibility index (PDI): Assesses functional properties.

Bulk density and particle size: Critical for packaging, cooking, and rehydration performance.

Microbial load: Total viable count (TVC), yeast, mold, and coliforms monitored to meet food safety standards.

Sensory evaluation: Color, aroma, and texture checked to maintain consistent consumer experience.

Modern extrusion lines incorporate in-line sensors for continuous monitoring, allowing automatic adjustments and real-time data collection. Batch records ensure traceability from raw soy intake to packaged product.

- Sanitation and Maintenance

Maintaining hygiene is crucial in human-grade operations:

Regular CIP cycles: Remove protein and oil residues without disassembly.

Lubrication schedules: Bearings and gearbox oil replaced according to manufacturer recommendations.

Screw and barrel inspection: Detect wear, erosion, or micro-cracks.

Calibration of sensors: Temperature and pressure devices recalibrated periodically.

Predictive maintenance using vibration and thermal sensors helps prevent equipment failure, reduces downtime, and ensures consistent product quality.

- Energy Efficiency

Energy efficiency is critical for operational cost reduction and sustainability:

Variable-frequency drives (VFDs): Optimize energy use of motors.

Heat recovery systems: Capture exhaust energy from barrel heaters for upstream conditioning or drying.

Smart algorithms: Minimize idle time and prevent over-shearing.

These measures reduce environmental impact while maintaining high throughput and product quality.

Summary

Optimizing the extrusion process and controlling key operating parameters are essential to produce human-grade soy protein ingredients that are:

Safe, hygienic, and consistent

Nutritionally rich and digestible

Texturally suitable for a variety of food applications

Compliant with international food safety standards

Proper process management, combined with automation, instrumentation, and rigorous quality control, ensures that human-grade soy extrusion delivers high-value, functional ingredients for the growing plant-based food sector.

Applications, Innovations, Market Trends, and Future of Human-Grade Soy Extruder

Human-grade soy extrusion has become a cornerstone of the modern plant-based food industry. As global consumer demand for high-quality, sustainable protein alternatives grows, extruders capable of producing safe, functional, and nutritionally optimized soy ingredients are increasingly essential. This section explores industrial applications, recent technological innovations, market dynamics, and the future outlook for human-grade soy extrusion.

- Industrial Applications

Human-grade soy extruders transform raw soy into a variety of high-value products for the food industry:

- Textured Soy Protein (TSP)

TSP is one of the most common outputs of human-grade soy extrusion.

Provides fibrous, meat-like textures suitable for plant-based burgers, sausages, meatballs, and minced meat analogues.

High hydration capacity allows reconstitution into desired textures during cooking.

- High-Moisture Meat Analogues (HMMA)

High-moisture extrusion produces continuous fibrous sheets resembling muscle tissue.

Moisture levels typically range from 50–70%, with controlled die cooling to preserve structure.

Used in premium meat substitutes and ready-to-eat meals.

- Soy Snacks and Breakfast Cereals

Low-moisture extrusion creates crunchy, expanded soy products for snacks and cereal applications.

Offers high protein content, shelf stability, and consumer-friendly taste profiles.

- Infant and Medical Nutrition

Extruded soy protein isolates and concentrates provide highly digestible ingredients for infant formulas, elderly nutrition, and clinical dietary products.

Neutral flavor and high digestibility make these suitable for sensitive populations.

- Technological Innovations

Modern human-grade soy extrusion benefits from several key innovations:

- High-Moisture and Co-Extrusion Systems

Allow the combination of soy with other plant-based proteins (pea, wheat, rice) for enhanced texture and nutritional balance.

Cooling-die technology enables continuous fiber formation and layered textures resembling natural meat fibers.

- Modular Twin-Screw Extruders

Barrel segments, screw elements, and dies can be reconfigured quickly.

Flexibility allows production of low-moisture snacks or high-moisture meat analogues using the same equipment.

- Advanced Materials and Coatings

Stainless steels, nickel alloys, and ceramic coatings resist abrasion from soy fibers.

Enhance lifespan and maintain compliance with EHEDG hygienic guidelines.

- Automation and Smart Controls

Sensors and IoT platforms monitor temperature, torque, pressure, and moisture in real-time.

AI-driven algorithms automatically optimize screw speed, barrel temperature, and moisture content for maximum efficiency and product quality.

Predictive maintenance reduces downtime and prolongs equipment life.

- Market Trends

The market for human-grade soy-based foods is growing rapidly due to:

Health and Nutrition Awareness: Consumers are seeking plant-based, high-protein alternatives.

Environmental Sustainability: Soy protein has lower water, land, and energy footprints than animal-derived proteins.

Flexitarian Diets: Rising adoption of flexitarian diets increases demand for meat analogues and protein-enriched foods.

Functional Foods Expansion: Extruded soy ingredients are incorporated into protein bars, bakery products, beverages, and ready meals.

Global projections indicate that the plant-based protein sector could exceed hundreds of billions of dollars by 2035, with soy extrusion technologies remaining central to this growth.

- Regulatory Compliance and Food Safety

Human-grade soy extrusion must comply with rigorous international food standards:

FDA and EU Food Safety Regulations: Ensure ingredient safety and proper labeling.

HACCP and ISO 22000: Frameworks for hazard analysis, risk management, and traceability.

EHEDG Guidelines: Hygienic engineering standards for design and cleaning.

CE and UL Certifications: Ensure electrical and mechanical safety of extrusion equipment.

Automation and digital batch tracking enable full traceability from raw soybean intake to packaged human-grade products.

- Sustainability and Environmental Impact

Human-grade soy extrusion supports sustainability through:

Energy Efficiency: Variable-frequency drives, heat recovery systems, and optimized screw designs reduce energy consumption.

Water Conservation: Extrusion requires minimal water compared to traditional cooking or soaking methods.

Waste Reduction: By-products, such as off-spec extrudates or okara, can be upcycled into high-fiber flours or secondary ingredients.

Carbon Footprint Reduction: Plant-based proteins produced via extrusion significantly reduce greenhouse-gas emissions relative to animal protein.

These practices align with global efforts to produce nutritious foods with minimal environmental impact.

- Future Outlook

The future of human-grade soy extrusion is shaped by technological advancement and market demand:

Hybrid Extrusion Processes: Combining soy proteins with cell-based or fermented proteins for enhanced nutrition and sustainability.

Customization: Advanced control of die configurations, screw elements, and moisture enables tailored texture, density, and flavor.

Global Accessibility: Soy remains abundant and cost-effective, supporting expansion into emerging markets.

Increased Automation: Full digital monitoring and AI optimization will become standard, improving efficiency and consistency.

Extrusion technology will continue to play a central role in the global plant-based food ecosystem, providing scalable, flexible, and sustainable solutions for human-grade protein production.

- Economic and Operational Advantages

Investing in human-grade soy extrusion delivers measurable economic benefits:

High Throughput: Large volumes of soy processed efficiently with minimal loss.

Flexibility: Multiple product types can be produced on the same equipment.

Reduced Microbial Risk: High temperatures and hygienic design extend shelf life.

Lower Operational Costs: Compared to traditional batch cooking or other protein processing methods.

Rapid ROI: Growing global demand for soy-based foods ensures fast payback on extrusion investments.

Conclusion

The human-grade soy extruder represents the intersection of mechanical engineering, food science, and sustainability. Its ability to convert raw soy into safe, functional, and nutritious ingredients has transformed the plant-based food industry. From textured soy protein and meat analogues to protein snacks and clinical nutrition, extrusion enables versatile, high-quality, and human-grade soy ingredients suitable for global markets.

By combining automation, hygienic design, process optimization, and sustainable practices, the next generation of human-grade soy extruders will enhance productivity, nutritional quality, and environmental performance, reinforcing the central role of soy extrusion in the modern food ecosystem.

In short, among all plant-protein processing technologies, the human-grade soy extruder remains one of the most important and impactful applications in producing safe, high-quality, and versatile soy-based foods.