Aqua feed Production: Essential Equipment and Processes for High-Quality Aqua feed

Discover the key equipment and technologies in aqua feed production. Learn how to produce high-quality aqua feed for fish and shrimp farming.

Importance of Aqua feed in Modern Aquaculture

In modern aquaculture, feed quality plays a vital role in the success of fish and shrimp farming. High-quality aqua feed directly impacts growth, health, and feed conversion ratios (FCR). Two main factors influence feed quality:

Internal factors: Quality of raw materials including protein, fats, vitamins, minerals, and hygiene standards.

External factors: Feed production equipment and processing technologies.

Even with premium ingredients, using substandard equipment can lead to poor-quality feed, reducing farm productivity.

Types of Aqua feed Based on Life Stage

Trout Feed

Starter Feed (SFT): Minimum 50% protein, up to 2 mm pellet size.

Fingerling Feed (FFT): 41–43% protein, 2.5–4.5 mm pellet size.

Grow-Out Feed (GFT): 37–39% protein, with probiotics and acidifiers for health and growth.

Shrimp Feed

Larval Stage: 41–43% protein, fine lightweight pellets.

Juvenile Stage: 39–41% protein, sinking pellets with good water stability.

Grow-Out Stage: 37–39% protein with feed additives for tissue quality and growth performance.

Key Equipment in Aqua feed Production

Raw Material Storage Silos

Galvanized silos protect raw materials such as fishmeal, soybean meal, and wheat gluten until processing begins.

Conveying Systems

Vertical conveyors (bucket elevators) and horizontal conveyors (screw conveyors) transport raw materials. Magnets remove metal impurities, ensuring feed safety.

Grinding Equipment

Hammer Mills for coarse grinding

Roller Mills for controlled particle size

Pulverizers for ultra-fine feed particles

Mixing, Pelletizing, and Stabilization

Feed Mixing Systems

Vertical and horizontal mixers ensure homogeneous feed formulations.

Pelletizing Systems

Feed is compressed through a pellet die, with diameters ranging from 1.8 to 6.5 mm depending on species.

Feed Stabilizers

Stabilizers provide secondary indirect cooking, enhancing feed durability, water stability, and FCR. L.lion stabilizers feature:

Double-walled thermal insulation

Steam coils and automated control

Stainless steel contact surfaces

30–60 min retention time with 0.3–0.5 MPa steam pressure

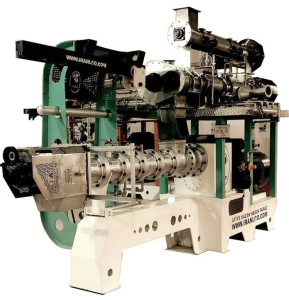

Floating Aquafeed Extrusion

Extruders produce floating aqua feed under 30–120 bar pressure and 90–150°C temperature. The process includes:

- Pre-Conditioning with steam injection

- Extrusion using a screw conveyor

- Cutting into uniform pellet sizes

Drying, Cooling, and Coating

Dryers and Coolers reduce moisture and temperature, preventing spoilage and mold.

Drum Coaters and Vacuum Coaters add fish oil, vitamins, and additives for better nutrition and palatability.

Crumbling Systems for Starter Feed

Crumblers break large pellets into smaller sizes (under 2 mm) for shrimp larvae and ornamental fish.

L.lion crumblers feature:

Adjustable roller gaps

Automated control systems

High precision with minimal fines

Single or dual motor configurations for capacity needs

Conclusion

The success of aqua feed production depends on selecting high-quality raw materials and using advanced equipment at every stage—from grinding and mixing to pelleting, extrusion, and coating. Modern technologies like L.lion stabilizers and twin-screw crumblers ensure superior feed quality, optimal FCR, and maximum productivity for fish and shrimp farms.

1 Comment