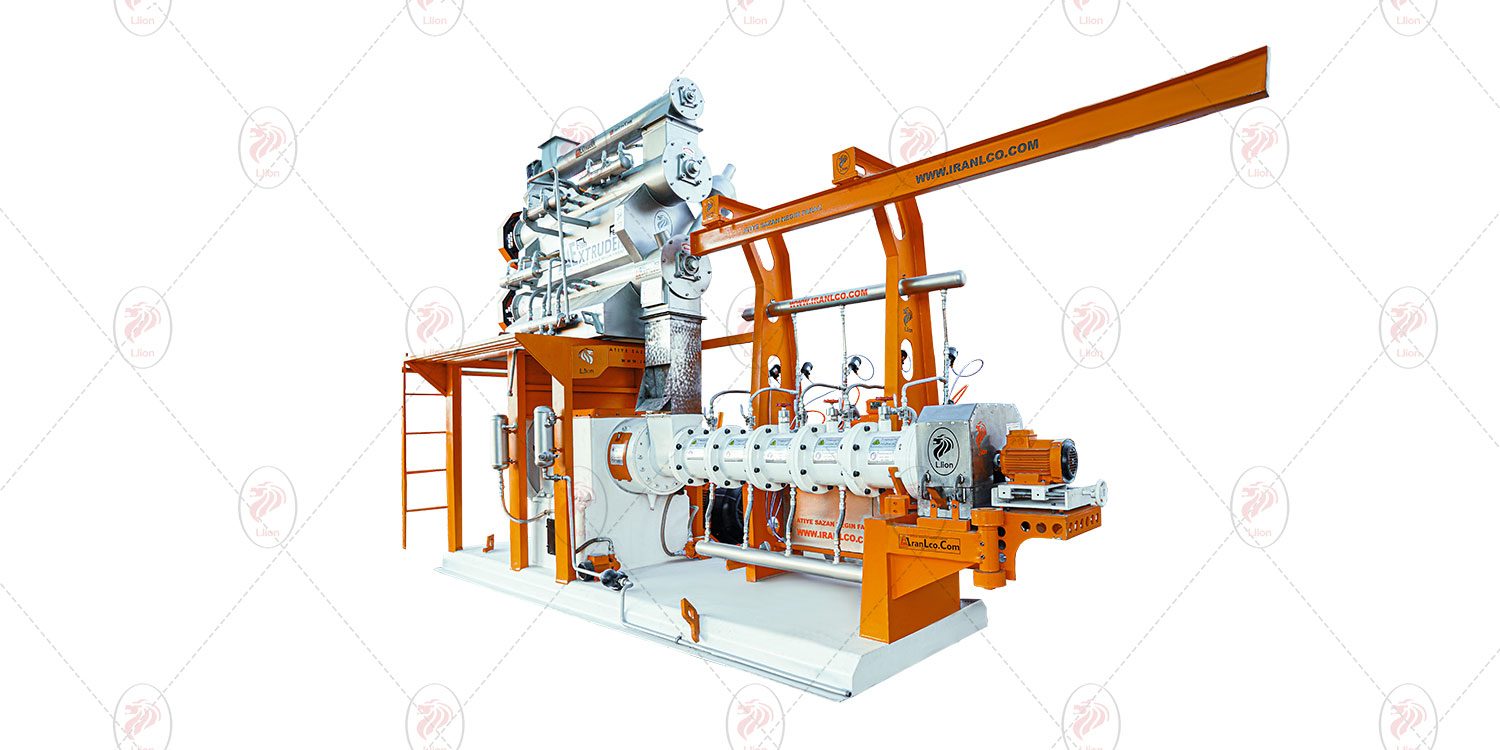

Shrimp feed extruder

Supplying the advanced industrial equipment technology and service for shrimp feed production is a response to the demand for high quality feed. Producing high quality shrimp feed depends on factors like raw materials and formulation, however, the equipment with the right attributes is of high importance.

In comparison to pelleting process, the extrusion process produces better nutritional quality feed. Although the extrusion process requires a high investment and its operational costs are higher than the pelleting process, it has the appropriate technology for densification, and is accompanied by a much greater profit and a better quality feed as a result.

Over recent years, lots of progress has been made to the extrusion systems to improve the shrimp feed in terms of physical characteristics, gelatinization of starch, sink rate, pasteurization, water stability and important properties with nutritional and environmental effects. Shrimp feed extrusion allows for producing a more nutritional high quality feed.

Today, the need for cost effective, and at the same time, high quality feed indicates that the best feed production requires a specialized processing technology. Atiye Sazan Negin Faraz is one of the leading companies in supplying technologies, systems, and services related to advanced industrial equipment for aquatic feed industry.

Advanced shrimp feed production technology

High quality shrimp feed production depends on factors like raw materials and formulation, however, the equipment with the right attributes is the key to the high quality feed production.

Shrimp feed extruder

This system is suitable for small-sized aquatic feed and uses the specialized die technology and high shear conditioner and is compatible with the process variables, such as moisture, temperature, cooking in pre-conditioner, and speed. The simplicity and flexibility of this extruder together with the new technology used in this system lead to the unmatched function of this distinguished feed. Due to the extrusion limitations for the 3mm≥ feed diameter, most producers tend to use feed pelleting with this size, but shrimp feed extruder meet this need.

Advantages of shrimp feed extrusion with high capacity versus conventional processes

- Ability to produce products less than 0.8 mm in diameter that are similar to pelted feed in terms of density

- More starch gelatinization

- Higher production speed

- Feed size uniformity improvement

- Better energy conversion

- Decreased formulation cost

- Great diversity in raw materials

- High degree of porosity

- Low degree of density

- High addition of liquid

- Longer water stability

- Less environmental pollution

Maximum density of product

Shrimp feed extruder de-aerates the mixture and maximizes density, giving the feed exceptional sinking features. The specific ring die used in this extruder improves the efficiency of the sinking feed. The cooking cycle time is increased due to the long rings and the expansion caused by pressure drop and the retention time is reduced. Moreover, the adjusted die design leads to a flow with uniform cross section and removes the extrusion of small-sized feed capacity limitations.

High shear conditioning

In comparison to the conventional conditioners, high shear conditioners increase the steam and water ratio in aquatic feed mixture. This causes the moisture and heat to penetrate more rapidly to the feed particles. Water and steam are injected to the end part of the large diameter conditioner. By reducing diameter and volume at the smaller end of the unit, the shear rate is increased and the product is exposed to the raised mixing intensity simultaneously. This results in 85 to 90% starch gelatinization in shrimp feed.

More flexible price

With advances in extrusion process, the high capacity extrusion process for small-sized aquatic feed and shrimp feed provides a more flexible feed recipe as compared with pelleted feed. For example, the protein level in the diet can range from 25 to 45% depending on the system. The fat level can also exceed that of the pelleted feed. Moreover, the extrusion process allows for using cheaper starch resources.

Increasing the potential profit

Shifting from shrimp feed pelleting to extruding can potentially increase the profit in various ways. An increase in the profit begins with higher production rate. Furthermore, extrusion leads to higher cost saving regarding feed production.